Laser & punching

Sheet metal is a modern and highly flexible construction material. The relevance of custom-made sheet metal parts is becoming increasingly important in industry.

Only through the use of high-quality, productive machines combined with experience and expertise can the production of such parts be realised.

At Henke we meet these requirements with the most modern CNC production technology and can also realise very specific project wishes through sensible performance combinations, from laser cutting to punching.

Technology

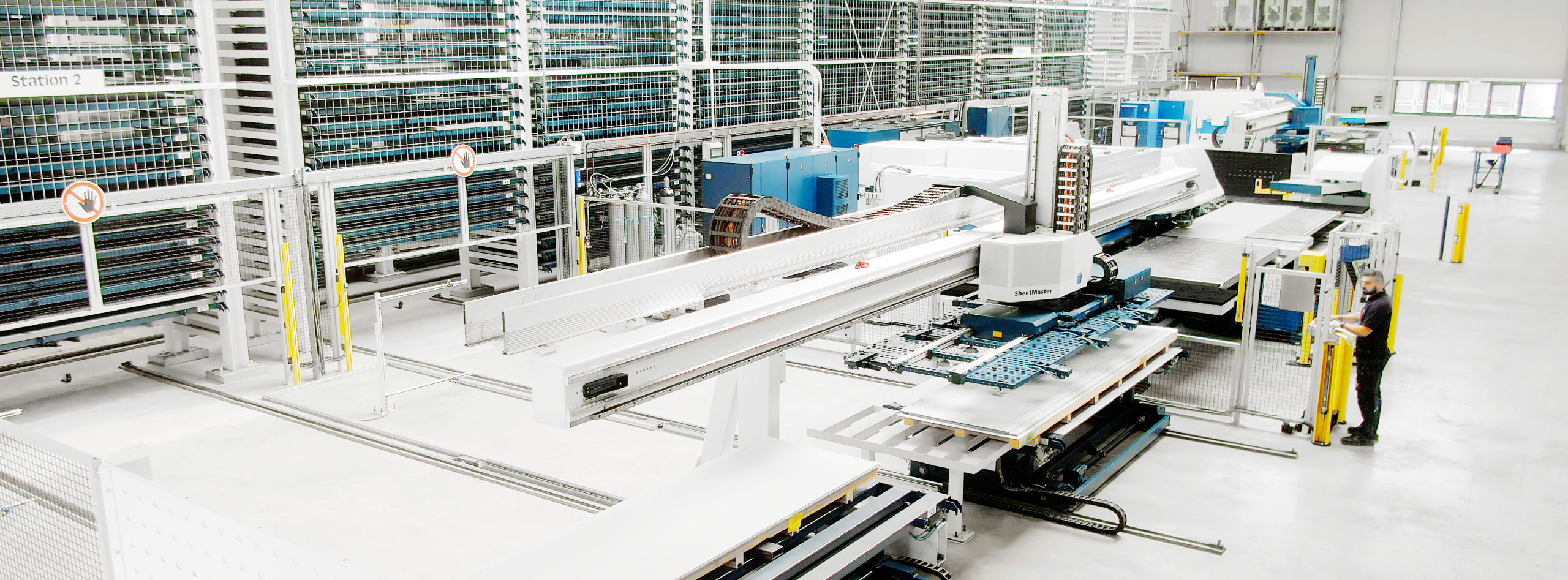

- STOPA materials storage

- Fully automatic materials storage

- Over 700 gross places of 3 t

- Set-up during machining

- Unmanned production

Laser cutting

Laser cutting enables absolute precision during production and, accordingly, burr-free cut edges. Our efficient machinery enables us at Henke to cut filigree contours even on thick steel elements. From small to large series, we implement the most diverse projects in the field of laser cutting – including in combination with punching.

Technology

- TRUMPF 5030 Fiber 5 kW

- TRUMPF 3030 CO² 3 kW

Punching

Thanks to our STOPA materials store, the finest punching work is carried out fully automatically and efficiently.

Technik

- TRUMPF Trumatic 7000

- TRUMPF TruPunch 5000